|

Solar Foundations USA receives a variety of questions regarding our products, services, and installation and design capabilities daily from clients both new and existing. Solar energy installers typically are well versed in the rooftop design and installation processes but often do not install a sufficient volume of ground mount structures to develop the same level of proficiency. That is where SFUSA comes in and we appreciate your company trusting us with your project needs.

Here is a list of the ten most frequently asked questions and the answers your company needs to make an informed decision and evaluate the site and design conditions of each project.

- What is the most cost-effective configuration for Solar Foundations’ structures?

- The most significant cost savings usually come with using our standard 6 Landscape design instead of a 5 or 4 Landscape configuration. Likewise, selling systems in increments of 6 panels (for the 6L system) whenever possible results in the best price point.

- Our standard 6 Landscape design is the most cost-effective and aesthetically pleasing solution due to the compact design and productive use of square footage. By selecting a 6 Landscape design, you are saving in areas such as beam length, rail mounting hardware, and pile count.

- Does Solar Foundations USA install custom structures?

- SFUSA can custom design to suit just about any needs your company may have. We can come up with creative structures and products outside of our standard systems for unique situations. Solar Foundations USA understands homeowners and businesses may have difficult requests for their ground mount structures. We work hard to identify those needs and create a pleasing design that is cost-effective and ensures every solar array design conforms to building code requirements and remains within the tested design parameters of each solar component.

- Does SFUSA install in portrait orientation?

- Solar Foundations USA can orientate panels in portrait, but we prefer landscape for the following reasons:

- In landscape orientation, we can support up to six panels on two rails. In portrait orientation, the most could be three panels on two rails. As the rails are one of the more expensive components, doubling the quantity required and associated cost is a prominent reason portrait orientation does not get pursued.

- While just about every panel manufacturer allows in-board clamps on the long side of the panels for landscape orientation, panel manufacturers seem to have varying restrictions for mounting to the short side with portrait orientation. Some allow rails to be in-board similar to landscape, others want continuous edge support, and some have varying other restrictions or special clamps.

- As our clients tend to change panels based upon last-minute availability, the landscape orientation is much more forgiving from a design perspective. Portrait orientation requires researching what is allowed for each panel model and the maximum uplift and downward pressures that may not be the same for another last-minute substitute panel manufacturer.

- If a panel manufacturer requires continuous long-side edge support for using portrait orientation, then we would likely need to increase the space between each panel column to fit the rails for two adjacent panel columns being side by side. We would need to go from our standard 1/4” to 3/8” gap to probably something closer to 2” depending on the particular panel frame and bolt holes.

- In that event, the array does get slightly larger, which results in adding more beam support length or even potentially an additional pile pair depending on the array size, thus adding cost.

- What information is required for Solar Foundations USA to schedule an installation?

- SFUSA requires four tasks to be completed prior to scheduling the project:

- Executed Solar Foundations USA Contract

- Solar Foundations USA provides a formal contract with the structural drawings and stake-out plan when the final design package is issued. The contract is sent through email as well as PandaDoc to your recommended office personnel upon request for an e-signature.

- Updated Stake-Out Photo

- Using the SFUSA stake-out plan, an updated site photo showing the four outside corners of the array staked-out is necessary.

- Access Path for Truck and Trailer

- Solar Foundations USA needs a satellite view showing how we can drive the truck and trailer to the array location (and photos if there is tight access). Please let us know if there are restrictions on driving the 48’ truck and trailer off the end of the driveway to the array area.

- Copy of the Project Permit

- Solar Foundations’ Operations team is facing a common issue of clients scheduling a project before it is permit-approved. Even though a client may have an idea of when they’re going to have permits in hand, nine times out of ten the specified timeline is not guaranteed. Because of this, projects have been dropping at the last second. This wreaks havoc on our schedule as each job is meticulously sorted for our crews to smoothly move from one installation to the next nearby with the proper material load on the trailer.

- Additional information regarding what is needed prior to scheduling an installation can be found here.

- What dimensions should my site tech use to stake-out the four corners of the array?

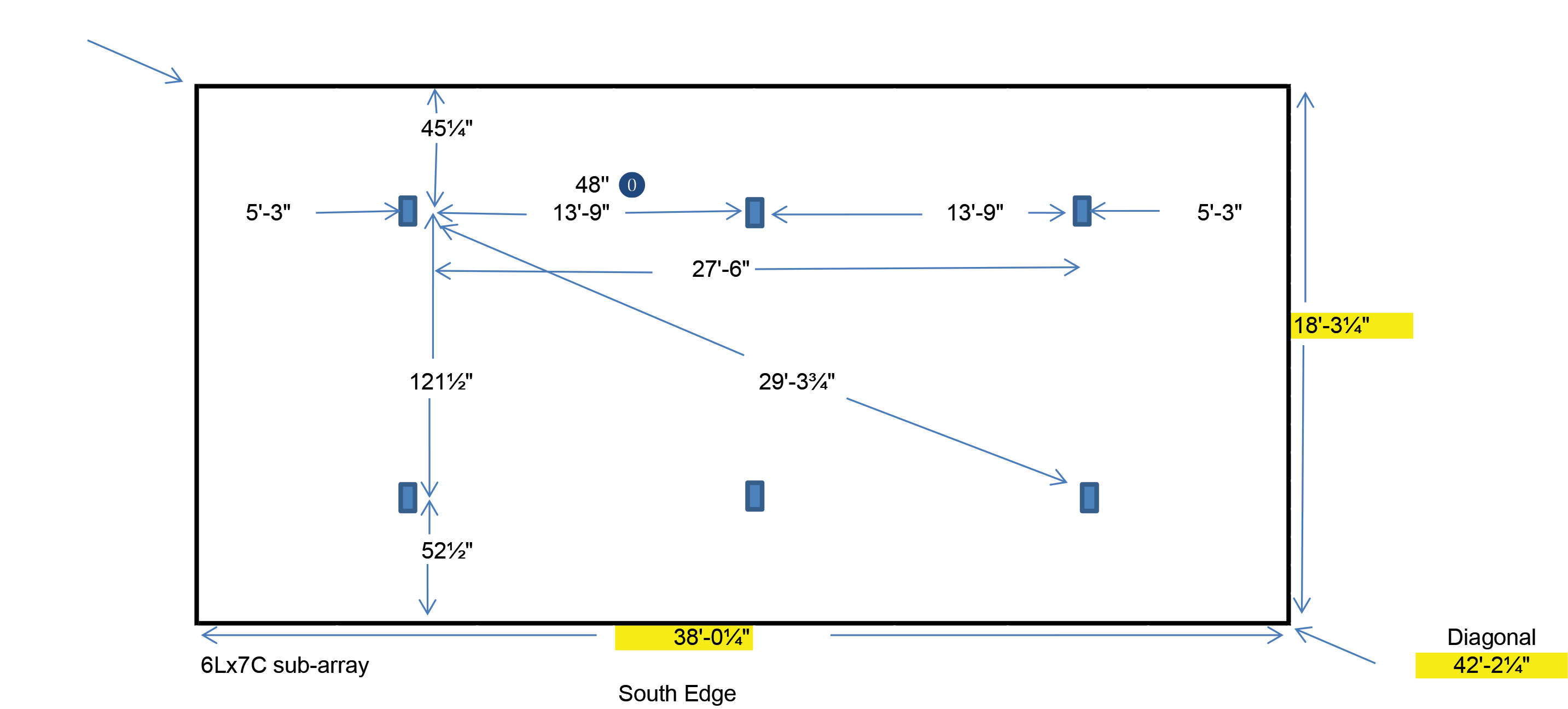

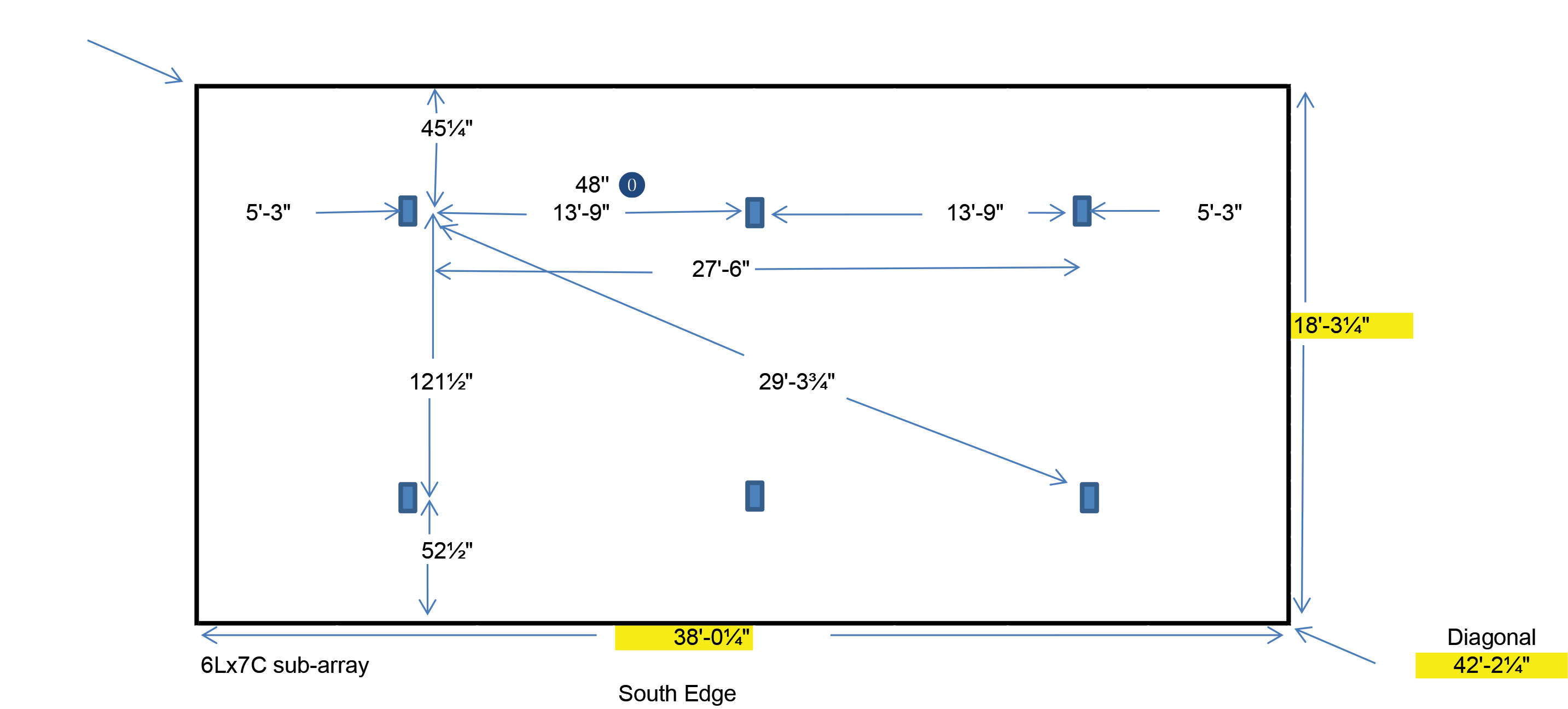

- SFUSA provides a stake-out plan once the project design is complete. The stake-out plans are a “Plan View” (looking from above the array to the ground). The only dimensions your company needs to use for the stake-out are the numbers highlighted in yellow.

- For this 6Lx7C example (6 panels high in landscape orientation by 7 panel columns wide), the 18’-3 1/4” is the north-south distance of the array projected onto the ground. The east-west dimension of the array is 38’-0 1/4”.

- What is the maximum slope Solar Foundations USA can install an array on?

- The array location is a critical piece of information that needs to be confirmed with the homeowner. The array location dictates matters such as engineering, materials, equipment, etc. The safety shut-off on the mini skid steers Solar Foundations uses to install the piles initiates when the ground slope is over 15 degrees (about a 32 in. drop in 10 ft.). When it is necessary to rock drill, we need to limit ground slopes to 10 degrees because of the drilling equipment (about 21 in. in 10 ft.).

- Anytime the site slopes more than 10” over the east-west length of the array, we will slope the array to follow the site contour. If there is ever a reason you need the array held level, you must provide actual grade elevations of the four corners of the array. Without grade elevations, we cannot design the system level and will not have the correct product on the equipment trailer when Solar Foundations arrives for the installation.

- What type of foundations does SFUSA install for the ground mounts, canopies/pavilions, and carports?

- Solar Foundations manufactures our Solar Continuous Flight Helical Piles with heavy wall structural tubing followed by hot-dip galvanizing. Our custom ground screws are used for most systems because of their uplift and bearing performance, ease and speed of installation, minimal disturbance to site and soil, and the ability to validate pile capacity during installation.

- Read more here on the advantages of using helical piles and ground screws.

- Where does Solar Foundations USA offer installation services?

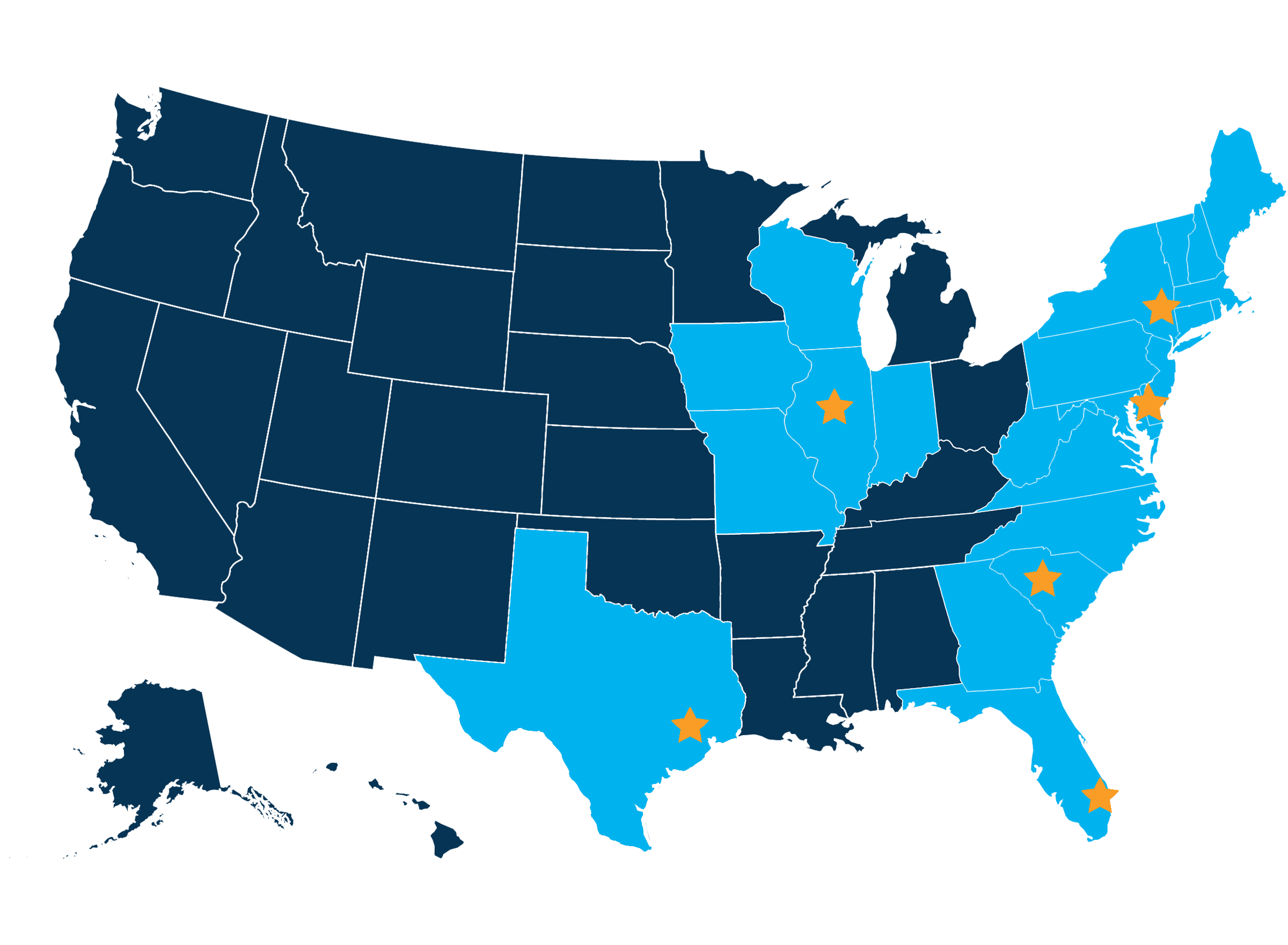

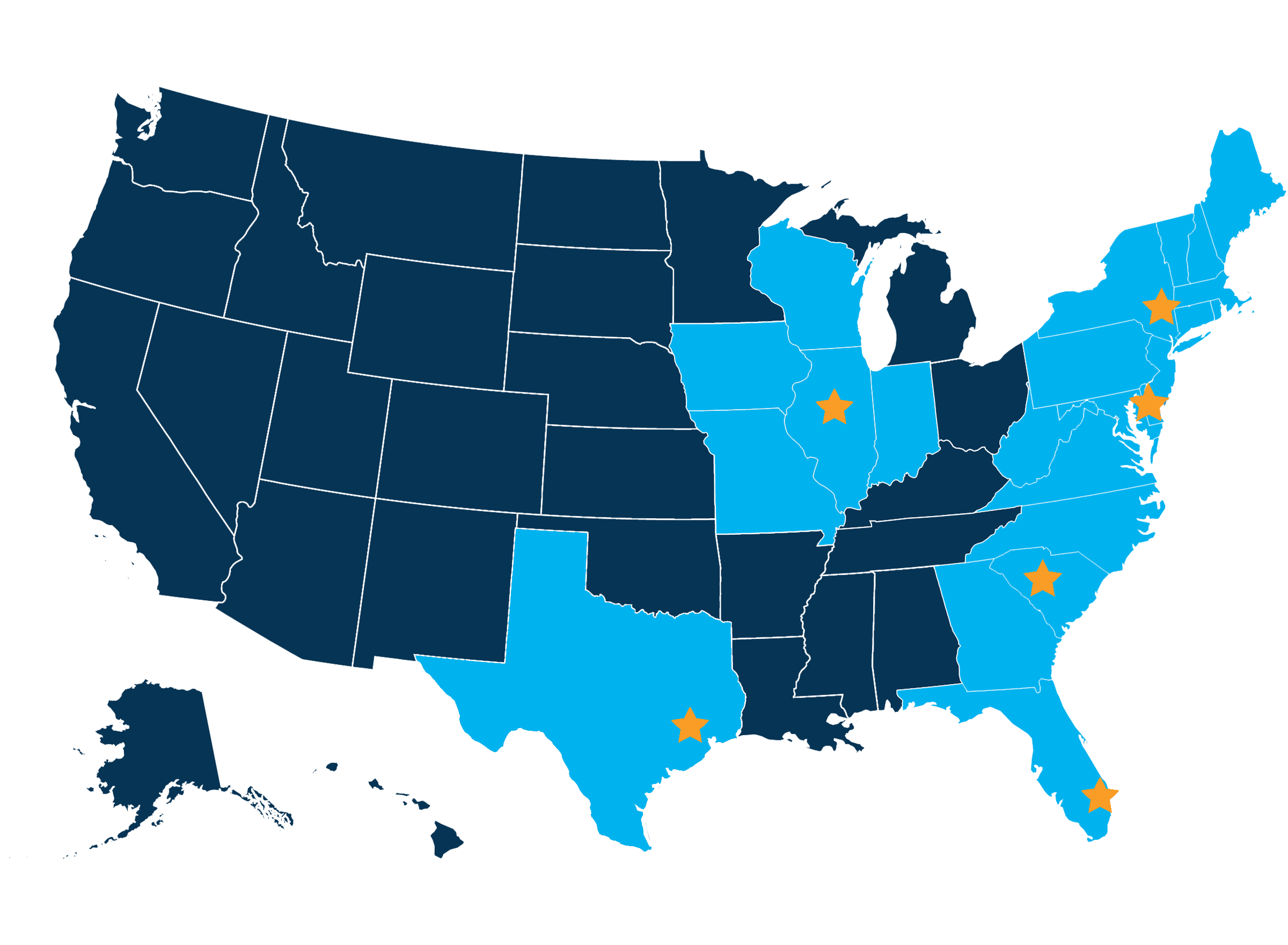

- Solar Foundations offers a full range of services including consultation, engineering and design, permit-ready plans, custom component manufacturing, and installation services all along the entire east coast from Maine to Florida, Texas, and now a portion of the Midwestern region.

- What type of optional equipment does SFUSA provide?

- Solar Foundations USA offers a number of beneficial add-ons for the SFUSA Ground Mount System. These features include equipment support columns for mounting electrical equipment, black panel mounting hardware for a sleek appearance, micro-inverter mounting hardware for a secure and simple connection, and torque limiters to maintain precise control when mounting solar panels to our structures.

- View Solar Foundations' Additional Items Brochure.

- How do I know whether or not rock drilling will be required at my project location?

- With over 2,500 installations along the east coast, we have discovered the best way to identify if there are possible rocky conditions is to ask the homeowner or business about their experience with their property. Solar Foundations USA also has the capability to look at projects close by to determine whether or not drilling or augering was required for a project prior.

- What has the homeowner found when he/she has dug on the property?

- Did the homeowner find the property full of rocks and/or highly compacted soil that made it difficult to dig posts for a fence, etc.?

- Did he/she put in an inground pool or know of a neighbor that put one in that encountered rock ledge that required blasting?

- Is there any exposed large rock at grade that the salesman can see?

- Normally when there is shallow rock ledge (i.e. less than 6 ft down) that requires drilling, the homeowner is well aware of the problem when they built the home or encountered water or septic issues due to poor drainage down through the solid ledge.

|

|

As Solar Foundations USA continues to expand across the US, we have seen many of the same questions about the ground mount installation process come up. Having installed thousands of ground mount structures, we have seen the good, the bad, and the ugly. As such, we found it fitting to begin creating these simple tips and tricks videos for our clients, both new and existing. As Solar Foundations USA continues to expand across the US, we have seen many of the same questions about the ground mount installation process come up. Having installed thousands of ground mount structures, we have seen the good, the bad, and the ugly. As such, we found it fitting to begin creating these simple tips and tricks videos for our clients, both new and existing.

Stay on the lookout for Episode #1 – How to Stake-Out the Array Area. Solar Foundations’ Communications Director, Meghan Matrazzo, will be walking you through step-by-step on why this is required, what is needed, and how to do it.

|

|

Solar Foundations’ President, Michael Zuritis, had the pleasure of speaking with Billy Ludt at Solar Power World regarding unique alternatives to rooftop solar for small-scale installations. With residential work being our bread and butter, Zuritis was excited to speak on our solutions and capabilities. Solar Foundations’ President, Michael Zuritis, had the pleasure of speaking with Billy Ludt at Solar Power World regarding unique alternatives to rooftop solar for small-scale installations. With residential work being our bread and butter, Zuritis was excited to speak on our solutions and capabilities.

Read the full article here.

|

|

Visit us at Booth #53 Visit us at Booth #53

June 9-10, 2021

The Westin Boston Waterfront

425 Summer St, Boston, MA 02210

SFUSA will be attending Solar and Energy Storage Northeast on June 9th and 10th in Boston, MA. Solar Foundations USA provides a full range of services including consultation, engineering and design, permit-ready plans, custom component manufacturing, and installation services. With your company’s new ground mount structure in place, you simply install the solar panels and remaining infrastructure, and the project is complete.

A common issue encountered with ground mount structures in the Northeast is the installation in difficult conditions due to dense or rocky soils as well as solid bedrock. Our crews have the ability to install our custom ground screws in any of these soil conditions by predrilling pile locations with the use of a carbide rock auger or drilling into solid rock with our down-the-hole hammer attachment.

Interested in booking a one-on-one meeting with our Sales Director, Devin Paris, while visiting the show? Follow the link below to reserve a time that works for you.

|

Visit us at Booth #53

Visit us at Booth #53